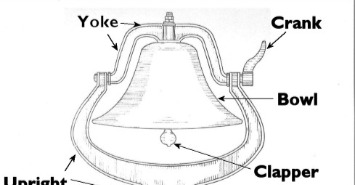

Cast Iron Bell Restoration

Begin restoration of a bell by using a wire brush to remove any

loose paint or rust particles that may have built up on the bell. You

could sandblast the bell if it is needed. After this cleaning, spray

paint the bell with a thin coat of Rustoleum primer to seal the surface.

Finally, the bell is given a brush coat of good grade machinery

enamel. Allow the paint to dry and the bell is ready. New bells are painted in the traditional color, black; but you can choose any paint

color.

Another method would be to protect

the clean metal surface with a coat of WD-40. This would maintain the

appearance of the metal and still protect it; however, a coat of WD-40

would need to be reapplied every year.

|

|

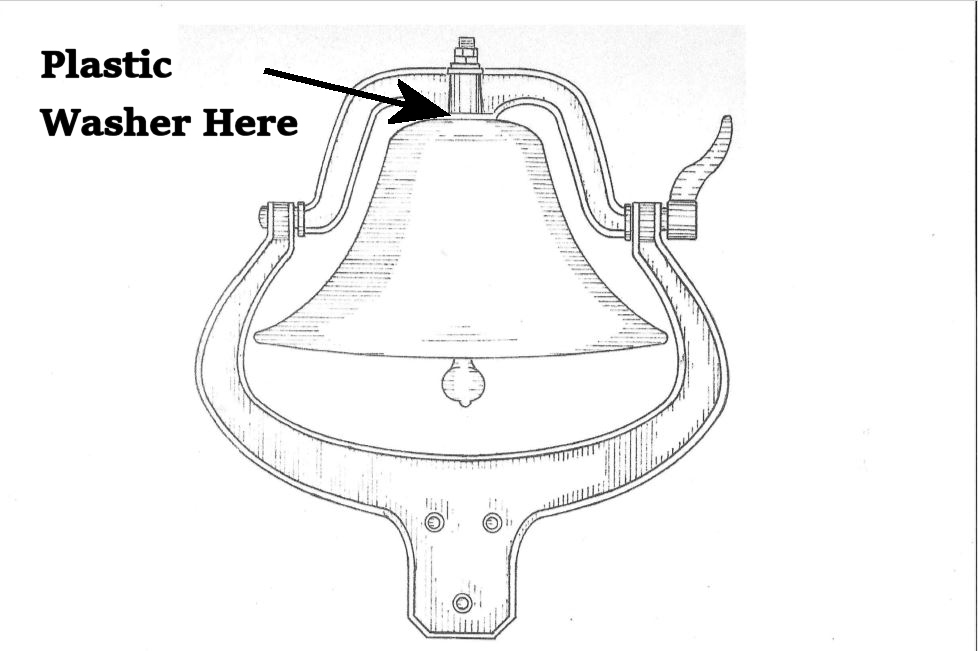

Fix Tippy Bell

Place or replace the plastic washer between the bell bowl and the

yoke. When you have the plastic washer inserted you can tighten and

straighten, tighten and straighten, until your bell assembly is tight

and hangs straight. If you do not have a plastic washer you can cut up a

plastic credit card in the correct shape and then the fix

is free.

|

|

Eyebolt Assembly

Prindle

Station Bells

eyebolt assemply available here.

You can purchase all the parts for an eyebolt assembly at your local hardware store.

This list is for a #2 Farm Bell:

- ½” eyebolt that is 3 ½” to 4” long

- A plastic washer to be placed between the bell bowl and the yoke.

- A metal washer on top of the yoke

- 2 square nuts to tighten and straighten the assembly.

- Assembly

the bell and mount it in the upright. Then straighten the assembly,

tighten the square nut, straighten and tighten until the bell hangs

straight and the eyebolt assembly is tight.

|

|

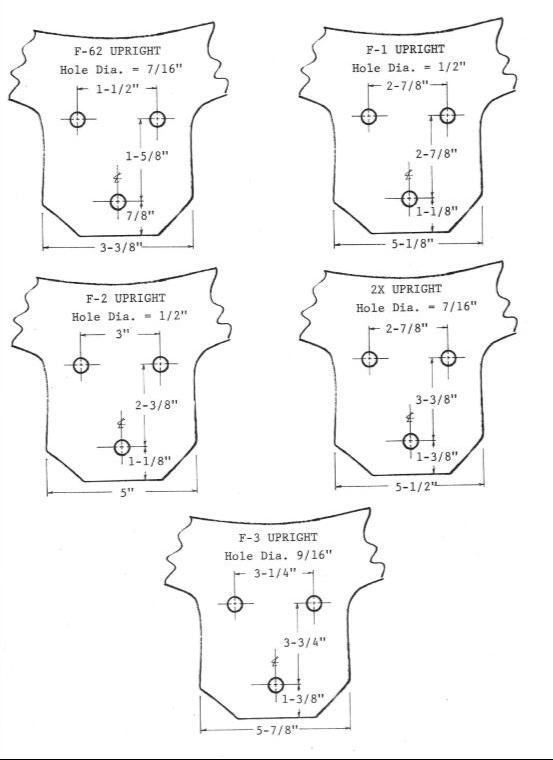

Mount Dimensions for bell upright

Make a Template for the drill pattern to mount your upright

|

|